Departments

Since 1950 SapiSelco has been working to design and provide customers with reliable, strictly Made in Italy products. The entire supply chain, independently managed at SapiSelco facilities, is divided into 5 departments: moulds, production, analysis lab, logistics and offices.

As part of a wider logic of continuous improvement, SapiSelco’s key priorities are employee health and safety, sustainability and maximized customer satisfaction.

Injection moulds:

from design

to production

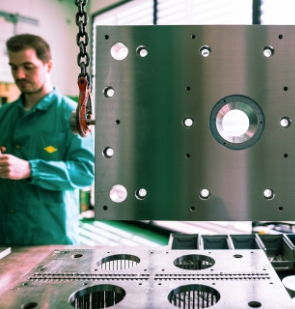

Mould department

SapiSelco independently designs and manufactures its own injection moulds. This task is entrusted to a team of engineers and specialized technicians in the Mould Department. This is where each new cable tie takes shape.

Design

A combination of know-how acquired through over 70 years’ experience and the most advanced development and modelling technologies (CAD/CAE) ensures mould design meets the highest quality standards, providing outstanding finished product performance in the various fields of application.

Production

Hardened steel is the raw material used to make the moulds, which are manufactured via a high-speed electroerosion and milling process. The use of CAM technology and CMM verification systems ensures extremely accurate manufacturing.

Quality and Safety:

goals to

improve

processes

Production Units

The entire manufacturing cycle, from raw material processing to finished product production, takes place in Italy at the SapiSelco plants, where automated work centres ensure an output of no less than 18 million cable ties per day.

Here, teams of specialised workers perform constant checks on work centres to ensure they are properly maintained and optimised. Production managers coordinate personnel and ensure compliance with health and safety procedures. The goal is to maintain, consistently and repeatably, the outstanding quality for which SapiSelco products have always been renowned.

The company figures speak for themselves

Analysis and development:

from raw material

to finished product

Laboratory

The analysis lab verifies incoming raw material conformity by analysing the moisture content, viscosity and density of the granulate. The lab checks that the values match the requisites indicated by production parameters.

Moreover, the SapiSelco lab performs quality controls on the finished product by way of daily sampling. The goal is to ensure all application needs are met in full by products that provide unmatched, lasting performance.

Quality

All SapiSelco products are put through lab tests. These are performed in a stabilised environment to verify compliance with international quality standards and product certifications.

The Supply Chain:

the focus of process control and improvement

Warehouses and logistics

SapiSelco operates globally and does business on over 65 markets worldwide. Logistics planning and shipments from plants are entrusted to the Logistics Department. The entire order management cycle (sales, labelling, packaging) is controlled by a WMS (Warehouse Management System), which allows:

- Order processing and planning simulation

- Pick list generation

- Optimisation of warehouse stocks according to the FIFO method

- Warehouse handling control

- Data flow synchronisation with ERP.

Computerization of the product management system and automation of the order fulfilment process ensures speed, reliability and flexibility, improving the services offered to customers.

SapiSelco,

a company with an

all-Italian heart

Office area

In keeping with our ‘Made in Italy’ philosophy, SapiSelco’s headquarters is located in the industrial district of Saonara, in the province of Padua.

Plants 1 and 2 house the office area, home to the following 6 departments:

- General Management

- Administrative Area

- Sales Area

- Purchasing Office

- Quality Area

- HR Area