Training Area

Get to know the SapiSelco cabling solutions so you always make the right choice. In this section you will find information on how to identify our product, application procedures, important information on storage, instructions on how to install the product safely, and advice on managing the used packaging.

Establishing SapiSelco product authenticity

Genuine SapiSelco products can be identified by their official hallmarks, which are stamped directly under the ‘head’ of each cable tie: here you will find the SapiSelco diamond logo or the 2S business code, two symbols that guarantee the item is a 100% Made-in-Italy SapiSelco product.

Storage and installation

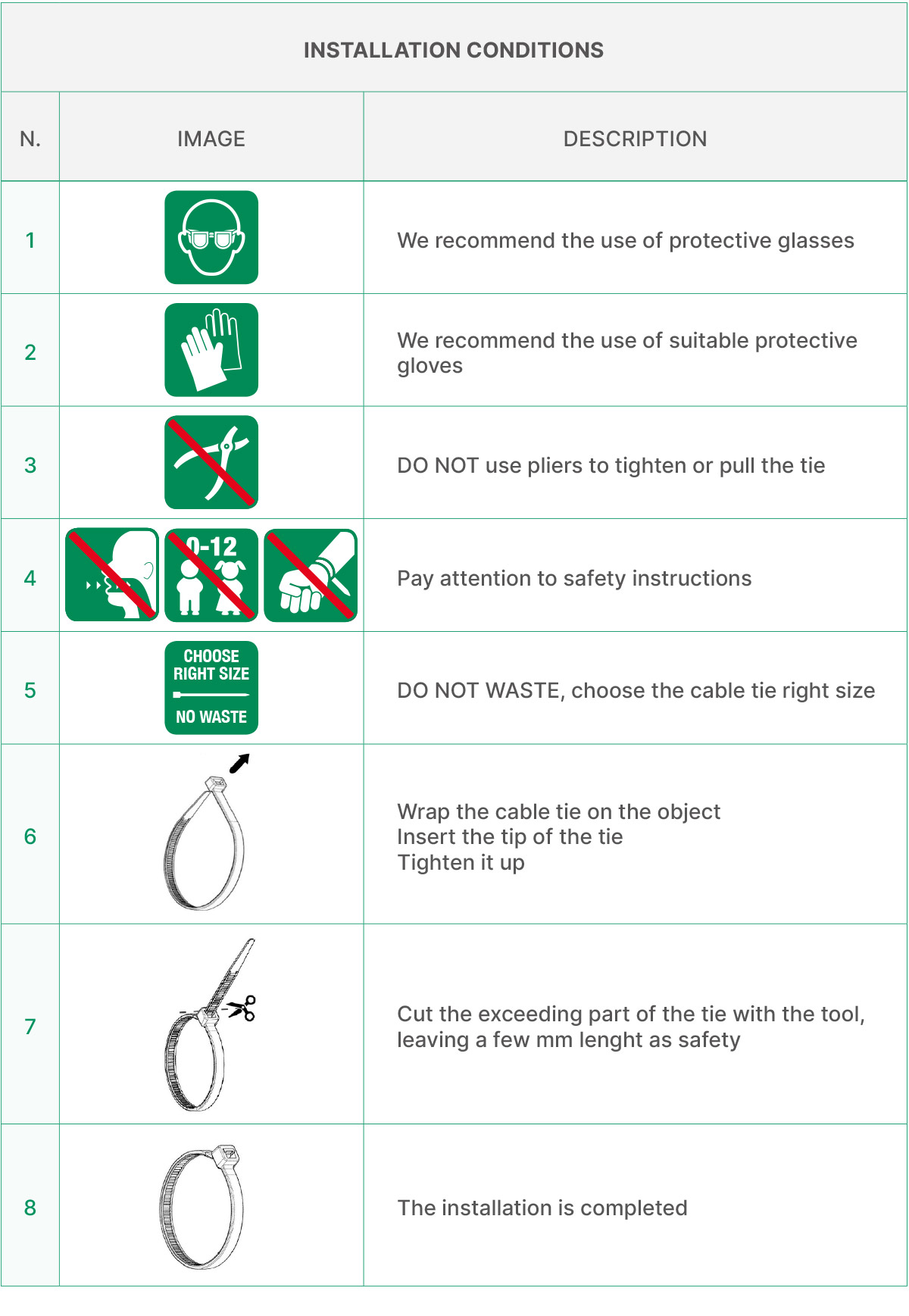

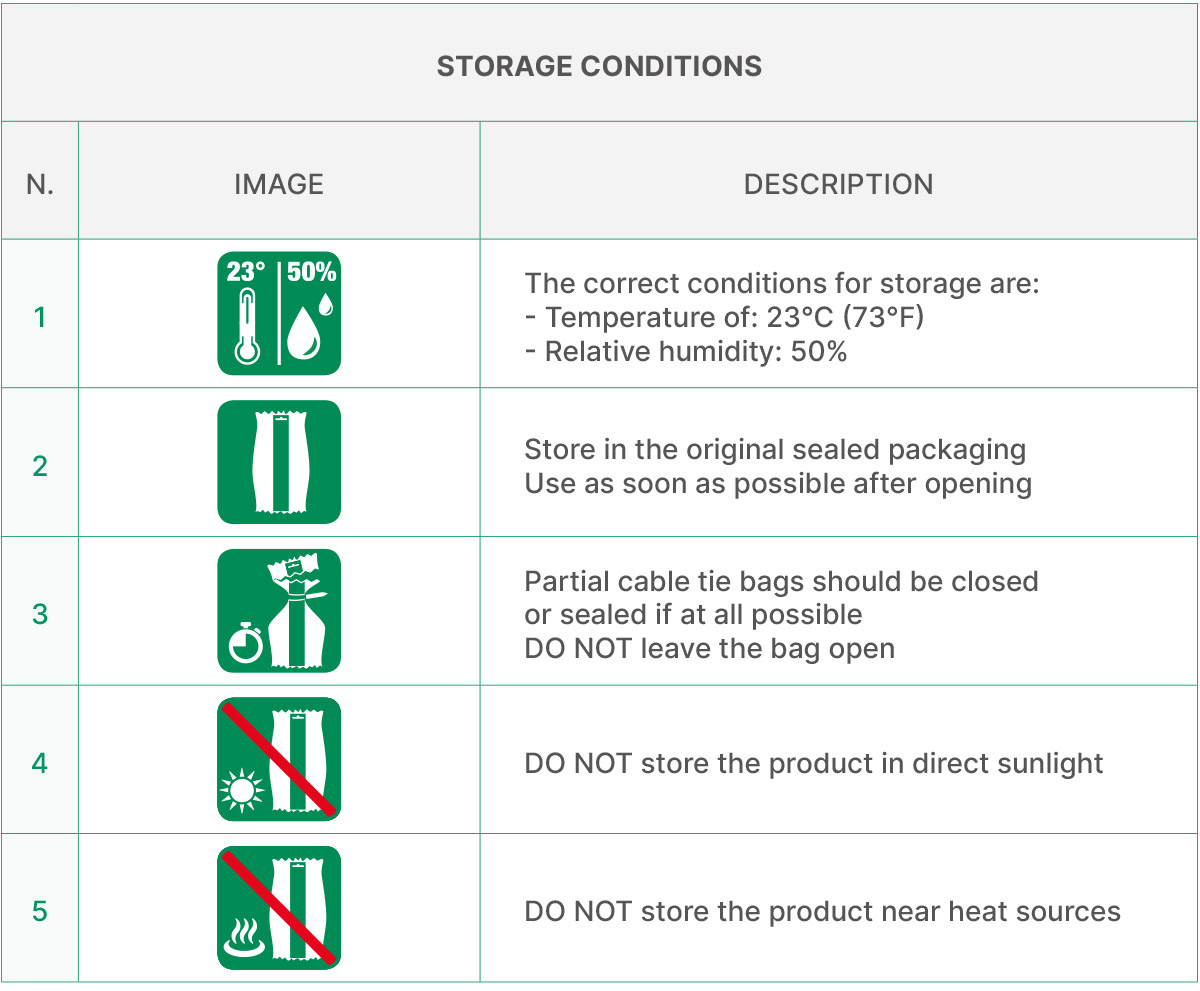

The following tables show the correct storage methods for SapiSelco products and provide information on the main application methods and safety standards.

Recycling instructions

To respect the environment and nature, in accordance with national and international regulations, see the following information on how to correctly dispose of packaging for all SapiSelco products.

Applying our product

An overview of the main fields of application for SapiSelco cable ties.

External factors that affect polyamide

Water

The relationship between polyamide and humidity and, more generally, water, is essential to understanding the behaviour of this hygroscopic engineering plastic. Like a sponge, the product absorbs and expels water as it adapts to the percentage of ambient humidity. The mechanical characteristics of polyamide products vary according to ambient conditions at the application site.

High temperature

Temperature affects the stiffness and flexibility of polyamide and subjects it to faster, irreversible deterioration.

SapiSelco provides cable ties in toughened PA66 that are ideal for high-temperature applications.

Click here to learn more

Low temperature

Low temperatures stiffen polyamide, making it brittle. Formulations suitable for use at low temperatures are defined as ‘toughened’ and offer better performance from a low-temperature brittleness perspective. Due to the effect of the toughening agent, the product self-extinguishing rating passes from V2 to HB.

SapiSelco provides cable ties in toughened PA66 that are ideal for low-temperature applications.

Click here to learn more

Sunlight

Exposure to sunlight, especially UV rays, is another contributing factor to the deterioration of polyamide. Over the years, SapiSelco has run simulated accelerated aging tests to compare items made with standard polyamide and UV resistant polyamide. The results of these tests mean the company is now able to provide a dedicated range.

SapiSelco provides cable ties in UV-resistant PA66. These are perfect for outdoor applications.

Click here to learn more

Fire

Another critical aspect for the safe application of polyamide products is fire. Keeping people safe, protecting property and reducing fire risks are all musts: hence the increasing importance of fire behaviour analysis, not just with building materials but plastics too. In the United States, such behaviour has been researched at length by Underwriters Laboratories, leading to the establishment of the UL 94 standard.

SapiSelco has chosen to produce most of its cable ties and accessories using polyamide 6.6, which belongs to UL94 self-extinguishing class V2.

For special applications, instead, cable ties made with PA66 are also available; these belong to UL94 self-extinguishing class V0.

Click here for further information

Chemical compounds

The characteristics of a plastic are also influenced by the ‘chemical environment’ in which it is installed. Polyamide has good resistance to chemicals and is particularly resistant to hydrocarbons, oils, alcohols, ketones and ethers. Other solvents such as strong mineral acids, metal salts and formic acid can, instead, deteriorate polyamide. When selecting a material for specific applications, one needs to consider the nature of the reagent, concentration, temperature and stress in order to determine the exact effect.

For the most aggressive chemical environments, SapiSelco provides cable ties made of PP.

Click here for further information

Storage conditions

Installation conditions